PLM system: the advantages of using the software

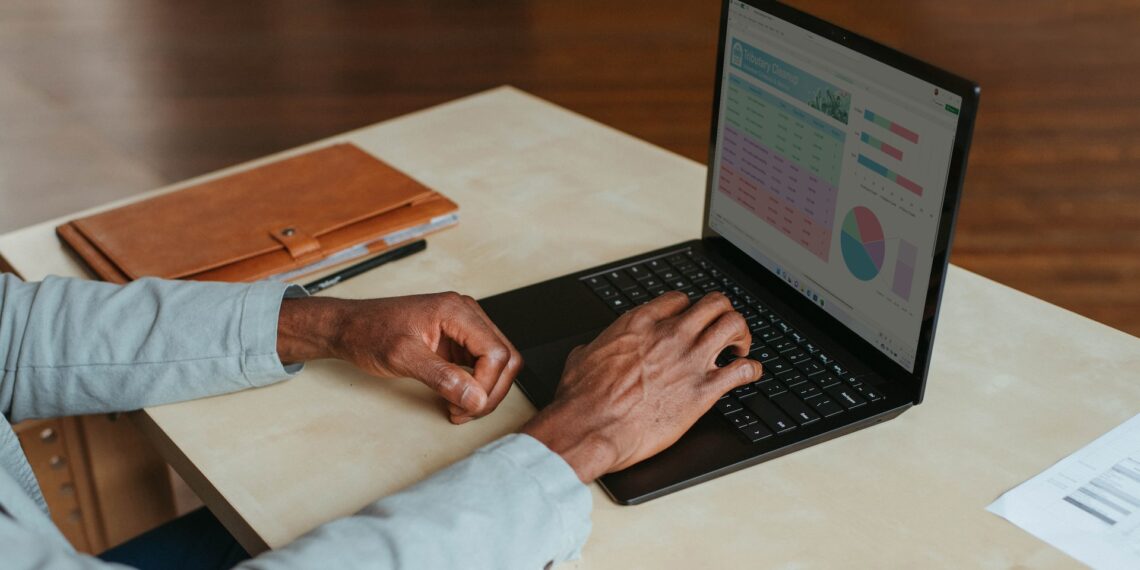

Companies that engage in full-cycle production have to deal with a huge number of processes and the processing of massive amounts of data. All this requires time and resources, and there is also a high risk of errors. PLM systems can help automate processes, accelerate them and increase their efficiency.

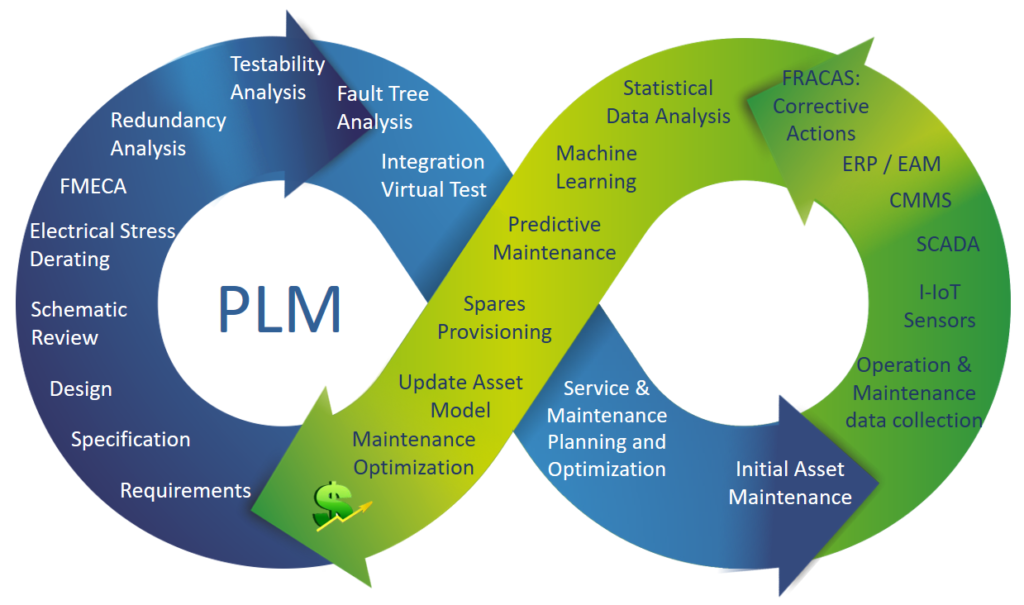

What is PLM? It encompasses all the operations of a product lifecycle management system. These systems are special software, which allows for optimizing production processes at each working step. In addition, the software allows a comprehensive approach to the creation of the product, taking into account the peculiarities at the stage of its development and operation.

Another important feature of the PLM system is the ability of complex analysis and integration with other systems, such as CRM, and ERP, thanks to which it is possible to control all the processes in the company.

Advantages of PLM system:

- helps increase the efficiency of full-cycle production, optimizing the time spent on each step. As a result, operating costs are reduced and productivity is increased;

- thanks to the PLM system, it is possible to think about all the features of the product, its use, and its promotion. As a result, the risk of force majeure during production is reduced, and all processes run faster, which also affects the speed of the market.

PLM system can be used for business in different spheres, it gives the opportunity to maximize the use of resources, reducing the cost of purchasing those or other elements. The faster the product is released on the market, the more profit the company can get, and the PLM system helps in this. In addition, the quality of the product increases, which contributes to higher sales and more customers.

However, it should be understood that any implementation of a new system requires patience and effort on the part of both management and employees. Automation does not happen overnight, and the effectiveness of product lifecycle management software will become apparent when it affects every process. You should be prepared for the fact that when implementing the system, you will have to re-engineer most of your business processes. It may lead to staff reduction, dissatisfaction, and rejection of progress. It is necessary to be prepared for this scenario and to consult with the team. It’s important to let people know that the PLM system will ease their work, take over their routine and enable them to concentrate on more valuable phases of production.

Consultants, who will take care of staff training, can help ease the process of transition to the new format of activity.